Nikon has developed a mirror box from engineering plastic for its ‘second-tier’ D810 model

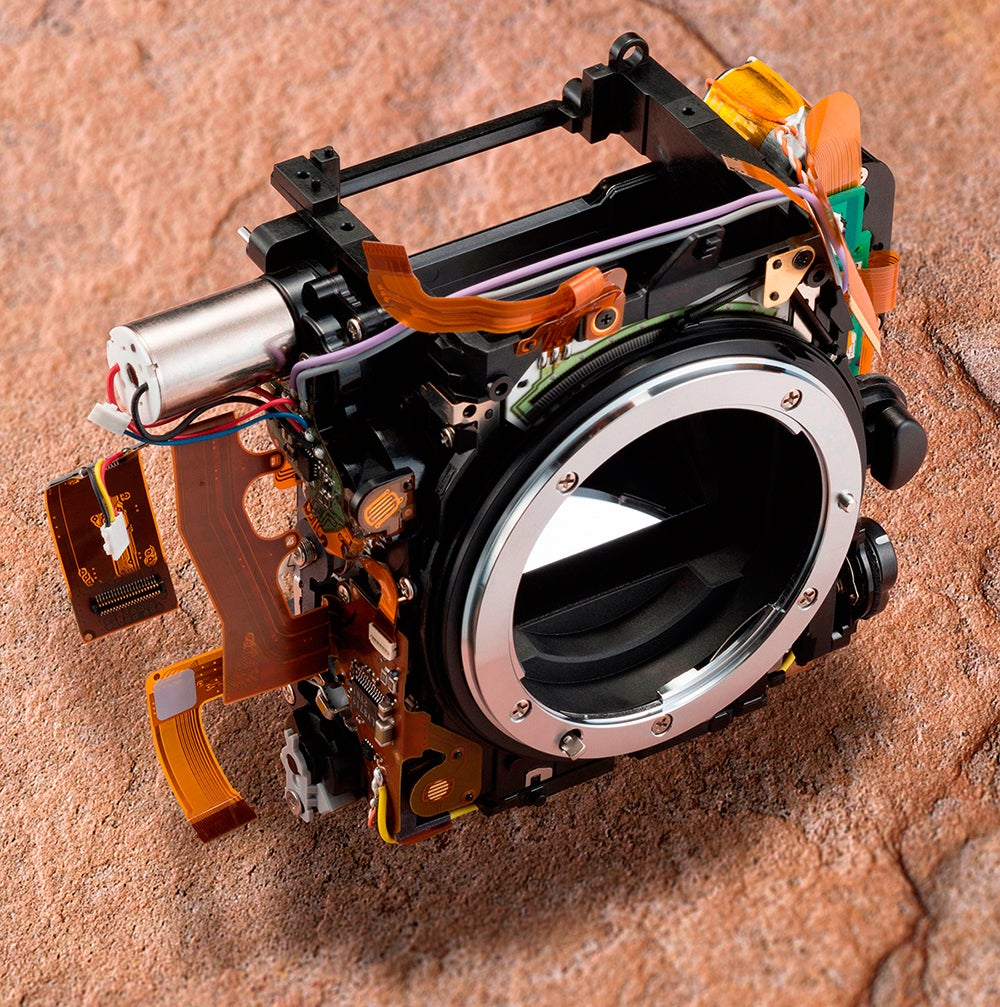

Most DSLRs use a plastic mirror box, like this one from the Nikon D750

Practically every DSLR that you can buy is based on the same basic structure. The central and most critical part is the mirror box. The reason that it is critical is that this part defines the optical alignment of the camera.

The lens fits on the front and the sensor fits on the back, and it is the role of the mirror box to keep them precisely the right distance apart (to ensure sharp focus) and exactly plane parallel (to ensure that sharp focus extends right across the frame). In addition, the mirror box must hold the mirror-flipping mechanism and resist vibration and movement as those parts move to do their job. As camera resolutions have increased, it’s become clear that the camera shake caused by these factors is significant.

In the majority of cameras the mirror box is constructed from a moulding of ‘engineering plastic’. The major advantage of this material is that it can be moulded in complex forms that can significantly simplify the number of parts required and reduce the amount of skilled effort needed to assemble the camera. Since cameras are still assembled largely by hand, this can be a significant saving in price. This advantage is used for all but the very top-end cameras, the only exceptions having been the Canon EOS-1D series, the Nikon single-digit series (D1-D4) and the Nikon second tier models, the D200, D300, D700 and D800, which have all had cast magnesium mirror boxes.

There is an open question as to how much advantage the metal box confers, since you see few complaints with respect to Canon’s second tier, the 5D and 7D series, which have a plastic mirror box.

R&D investment

Now seems to be a good time to think about the question again, since it has become apparent that the latest Nikon second-tier model, the D810, has a plastic mirror box, unlike its predecessor. It’s unlikely that Nikon has made this change to reduce manufacturing costs – it would have required a significant change in the tooling which itself must have required R&D investment. Instead, the change could derive from a desire to improve the product.

The respected Nikon specialist Thom Hogan revealed a couple of years ago that there was a significant occurrence of a problem in the original D800 – if the camera were dropped it could suffer a brittle fracture in the mirror box, which left the sensor misaligned even though there was no exterior sign of damage. It is possible that the change to the more resilient carbon-filled polymer is a response to this problem. A second design goal for the D810 was to produce less sensor vibration during exposure, to maximise use of the camera’s 36 megapixels. One measure taken was the fitting of a new lower-vibration shutter. The additional acoustic damping of the polymer mirror box will also have helped.

Bob Newman is currently Professor of Computer Science at the University of Wolverhampton. He has been working with the design and development of high-technology equipment for 35 years and two of his products have won innovation awards. Bob is also a camera nut and a keen amateur photographer